Monty's Workshop

My Workshop is my 2 1/2 car garage, with most of my larger tools on rolling platforms so that they can be set up for use, then rolled aside when they are not needed.

The "standard" woodworking tools in my arsenal are mostly old, vintage tools from the 40's, 50's and 60's. I like restoring these old cast iron gems with fresh bearings and motors, to breathe another half century of use out of them.

The new "fancy" computer controlled CNC Router and Laser also live on rolling platforms, but these also flip vertically, so the square footage needed for storing the toolbeds is reduced.

A wall mounted dust collection system protects my lungs (when I remember to switch it on).

Getting CNC tools is a real game changer! Repetative tasks can be executed with precision and speed.

In the first picture you see the router cutting out one large round cutting board.

In the second picture you see the router cutting out four smaller cutting boards.

I initially purchased the CNC from a friend of my friend, named Phil. After getting it back from Michigan and setting it up, my best friend Dave sent me a total upgrade package for it. New servos, controller, Z Axis unit, the whole schmeer. It took over a week to disassemble and reassemble the CNC, but I built a second cart and used the "leftover" parts to complete the Laser CNC shown below.

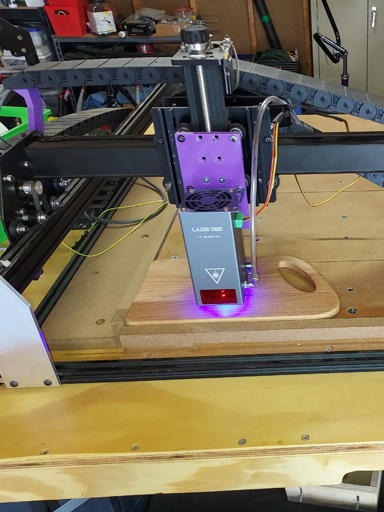

It took longer than I wanted due to many household maintenance projects, but the CNC laser is up and running at last!

In the first picture you see the starting to burn a pattern on a small cutting board.

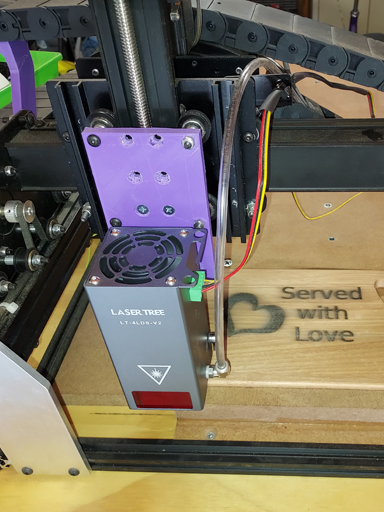

In the second picture you see the laser parked at the "Home" position after finishing the job.

This is really a "Franken-Laser", with parts from multiple vendors, parts I fashioned myself, custom programming and the like. So, not an "off the shelf" unit.

The heart of any wood shop, the table saw. I actually have 2 mounted side by side so I can keep one with a dado stack on the spindle.

The saw on the left is a 1950's model I restored, after having picked it up on Craigslist for just 20 bucks. The saw on the right is a "newer" 1960's model, also found on Craigslist.

The saw platform has an integrated folding outfeed table I made.

My Miter Saw rests on a rolling platform I modified to include accessory storage as well as folding side wings to support pieces being cut.

This saw is not vintage, it is just a Harbor Freight cheapie, so I've been watching for any opportunity to upgrade.

I really love my old 1940's vintage Jointer. This tool is extremely solid, massive and heavy, which means IT does not move while I am pushing lumber through the cutters.

Upgraded for 220 volt use, with a newer, heavy duty motor and new link belt installed.

This is one of the tools that makes using reclaimed lumber possible.

Hand in hand with the Jointer is the Thickness Planer.

I got this from my buddy Steve when he decided to throw in the towel on woodworking.

I built this custom 180 degree flip top tool cart, because the next tool to show is underneath the Planer...

I also got this from my buddy Steve when he decided to stop woodworking.

The flip top tool cart allows for double the tool storage and use for the same small 4 square foot floor space.

Here is my restored 1955 Craftsman Lathe. A fellow father in my son's scout troop, Chris gave this to me, but in fairly sad condition. New motor, belt, bearings, chuck, stripped, de-rusted and repainted.

I built the rolling stand with PVC tubing to hold the set of Chisels.

The first "real" thing I made were the tapered masts for the Freighter Models.

The next thing was an overweight baseball bat for my childhood buddy, Dr. Lucas.

When Debbie and I bought this house back in 2020, the garage roof rafters needed to be rebuilt.

After that rather arduous task was done, I used the leftover pieces of 2x8 and 2x6 lumber to fashion a solid, usable workbench with built in vises and bench dogs.

Here is a rare photo of the table while it is clear.

3D Printer Fleet

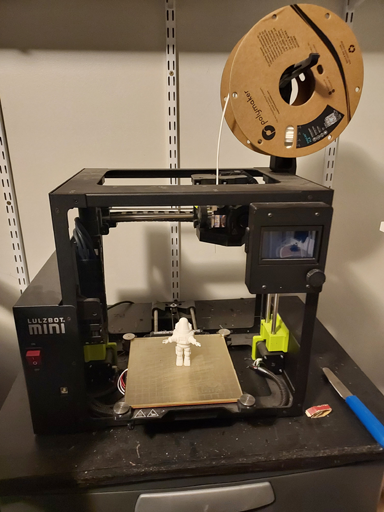

The Oldest of the bunch, and my over-all "go to" workhorse, is the venerable Lulzbot Mini 2.

I have squeezed literally kilometers of filament through this durable and hardworking machine.

I recently sent it back for a factory refurbishment, and hope to keep it in service for a few more years.

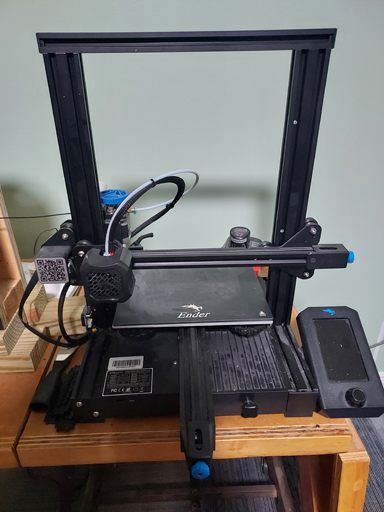

This Ender printer was a gift from my best friend Dave. He sent it to me while I was in "exile" in South Carolina working at a Dept of Energy Nuclear Site.

It's since been in service back in Kentucky, cranking out very fine prints, although at a rather slow feed rate.

Patience with this machine is rewarded, as the final print results are generally excellent.

The latest addition to the printer array is this Bambu X1 Carbon printer.

Again, this was an all too generous gift from my friend Dave, who I am convinced is living his model making life vicariously through me.

This is an amazing piece of equipment! It is 4x faster than the Lulzbot, and 6x faster than the Ender! The Print Volume is HUGE, and the first big, stupid thing I printed was this replica Mercury Astronaut Helmet. Outrageous!

Milo, the shop robot

I built Milo the Robot way back in 2015. While I tried to justify his construction in many ways, the simple truth is that building him was therapy against clinical depression.

I conducted experiments with Milo with respect to Machine Vision and Neural Nets. Got him to recognize and count faces, follow a safety orange colored vest and a few other vision related things. The main thing I learned is that I needed a way bigger budget.

Anyway, since he's joined the Guild Of Labor Devices, Bionic, Robotic, Intelligent & Computer Controlled, he's been nearly useless. Hard to get a lick of work out of him. He just sits on his charging station all day, drinking 10W-30.